- Top: 98Step on: 39

metal trusses price

People involved | Date:2025-08-15 08:16:49

Related articles

Moreover, automatic spray painting machines are at the forefront of sustainability efforts in manufacturing. They are engineered to maximize paint utilization, significantly reducing wastage. This has a dual benefit it lowers operational costs and minimizes the environmental footprint. Additionally, these machines can be equipped with advanced filtration systems that capture overspray, further mitigating environmental impact and complying with regulatory standards.

automatic spray painting machineThe Advancements and Importance of Automatic Ink Dispensers

In conclusion, poussière de soudure presents a significant health threat to welders and workers in related fields. The implications of long-term exposure to welding fumes extend beyond respiratory problems; they encompass neurological and carcinogenic risks that can alter the lives of workers dramatically. By implementing stringent safety measures, promoting awareness, and prioritizing workers' health, industries can create a safer environment for those engaged in welding activities. The time has come for companies to take decisive action to transform the welding workspace into a healthier one, ensuring that the very process that connects metals does not come at the expense of human health.

Shipping companies must adhere to strict international safety standards to ensure the integrity of their operations. The International Maritime Organization (IMO) and the International Organization for Standardization (ISO) have established guidelines governing the safe loading and stacking of shipping containers. Stacking bars are specifically designed to comply with these regulations, highlighting their critical role in maintaining safety across the maritime shipping industry.

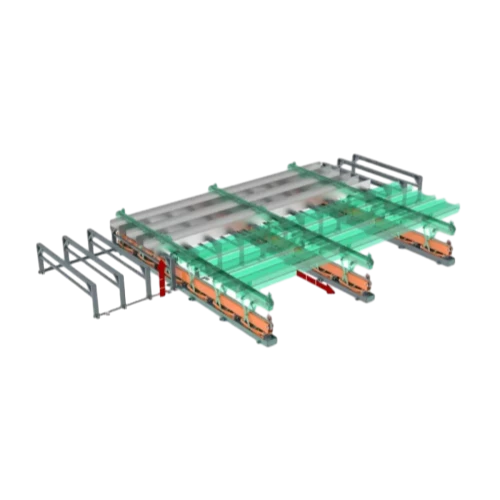

Enhancing Efficiency with Steel Structure Manufacturing Equipment

The mobile welding fume extraction unit is designed to be easy to transport and operate, offering robust performance without compromising on safety or efficiency. This is particularly valuable in facilities with dynamic production needs, where welding stations might frequently change locations or require adjustments. Integrating a mobile fume extraction unit with welding arms is the perfect way to achieve a safer and more flexible working environment.

What is an Exhaust Arm?

However, there are challenges to address. It is essential that as this movement grows, it remains rooted in the communities that birthed it. Ensuring fair compensation, preventing cultural appropriation, and fostering authentic representation are critical facets that need to be monitored and protected.

For those considering the transition to automated systems, understanding the initial investment versus long-term gains is essential. While the upfront cost may appear daunting, the return on investment is realized through improved throughput, lower labor costs, and reduced material waste. Consulting with experienced professionals during the planning and implementation phase is crucial, as they can provide insights tailored to specific industry needs and operational scales.

In the modern manufacturing landscape, robotic welding has emerged as a pivotal technology, revolutionizing the way industries approach production. As the popularity of robotic welding continues to rise, so does the attention to the essential aspects of workplace safety and environmental control. One crucial element in ensuring a safe working environment is the implementation of efficient ventilation systems tailored for robotic welding processes.

It's advisable to use a container to catch the fluid for proper disposal It's advisable to use a container to catch the fluid for proper disposal

It's advisable to use a container to catch the fluid for proper disposal It's advisable to use a container to catch the fluid for proper disposal

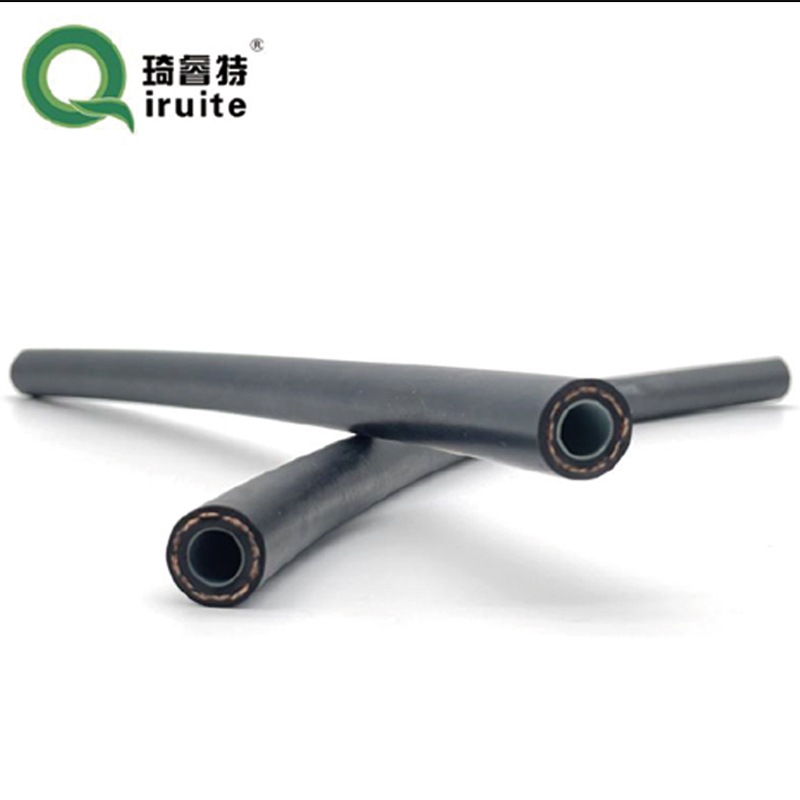

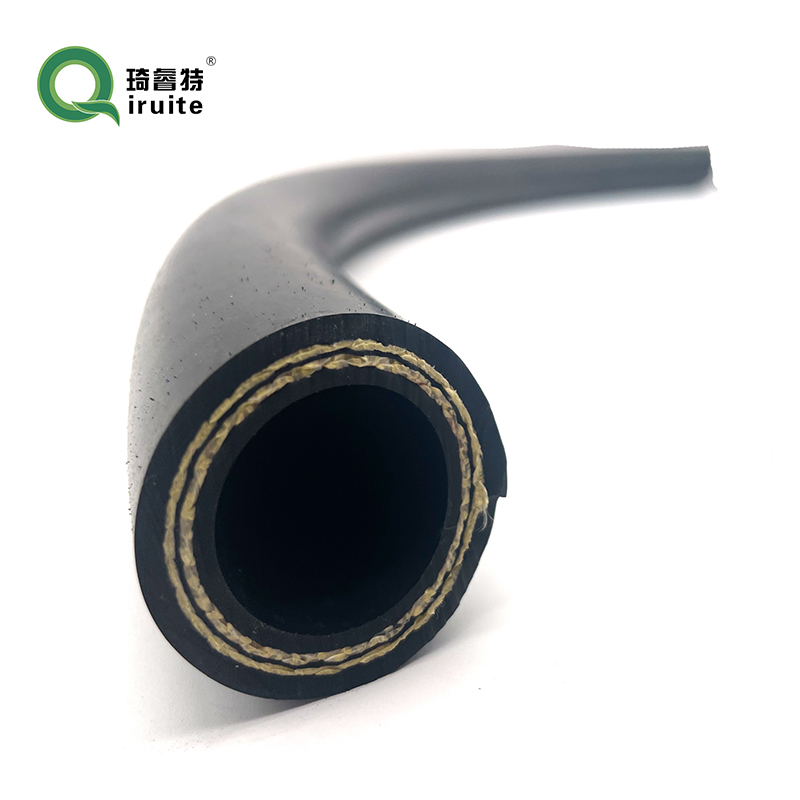

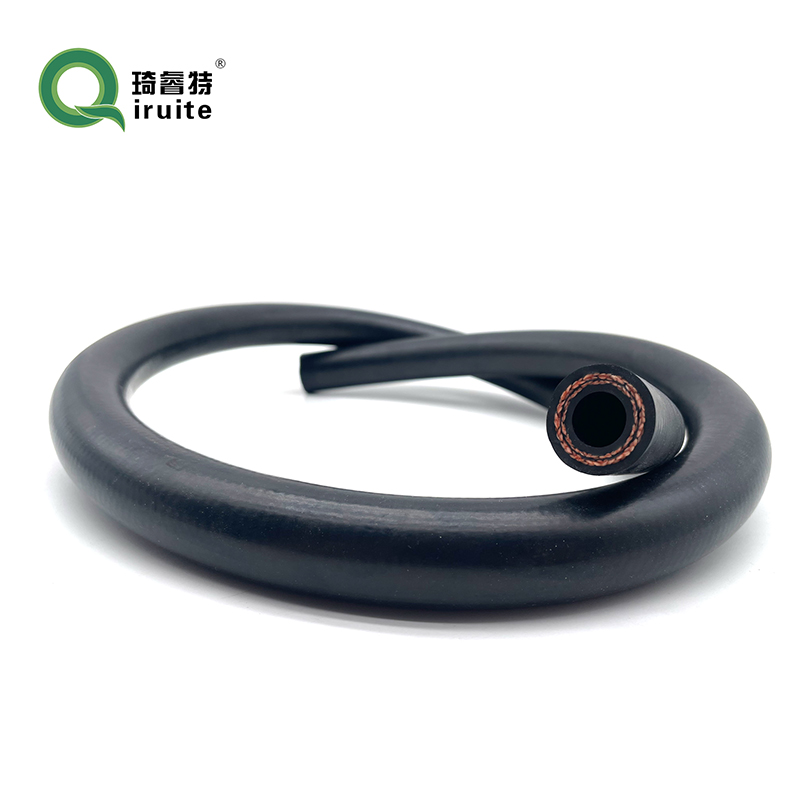

They are designed to join sections of pipe while maintaining the integrity of the system They are designed to join sections of pipe while maintaining the integrity of the system

They are designed to join sections of pipe while maintaining the integrity of the system They are designed to join sections of pipe while maintaining the integrity of the system

Comment area